TOPSFLO Helps the World’s Leading Medical Technology Company Realize the Breakthrough of Zero Impurity Technology for Medical Deionized Water Pump

2021-07-15

Recently, TOPSFLO made another great breakthrough in the field of raw materials R&D for Brushless DC water pump TL-C01, which was provided for client’s medical equipment, successfully passed the one-year "none particle testing", and realized zero impurity precipitating out in the real operation process. This marks that TOPSFLO brushless DC water pump has taken a leading position in the medical industry of none particle medical water pump.

The client in the case we share here, is a world-leading Medical Technology Company, whom is a Fortune 500 company with 10,000 of R&D members around the world. Their technology influences more than 70% of global medical equipment solution.

Challenges to the Circulating Pump of Medical Equipment Project

In July 2019, this medical equipment company sent E-mail to TOPSFLO: “enquiry TOPSFLO circulation pump, but it cannot generate any particles that may caused by abrasion.” In the process of further communication, we learned that they needed a dc circulation pump for medical equipment. Considering the pumped liquid for deionized water, the client required extremely high purity during pump operation. Previously, this client had tested many pump from worldwide brand, such as Japan pump and German pump. However, all of them came out with obvious particles or powder in the real testing, that caused pollution to the deionized water.

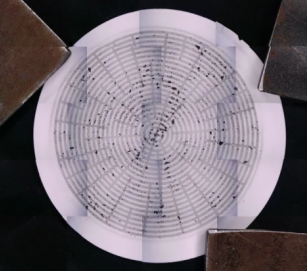

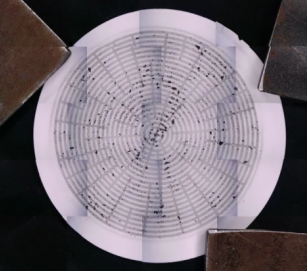

Picture: the test results of other brand circulation pump:

Solution from TOPSFLO

The safety of raw material used in water pump always a key focus of TOPSFLO. TOPSFLO sales engineer convey client’s requests to R&D Dept., and project established immediately. According to other clients in the medical industry experience, TOPSFLO R&D Dept. Engineer proposed that to change the traditional shaft sleeve into a wear-resistant shaft sleeve, and upgrade ceramic shaft to special medical shaft which with higher hardness and more wear-resistance, the black PPS was changed to a natural medical grade PPS.

At the same time, in order to meet required parameters of this client, TOPSFLO provided them with the customized TL-C01 brushless dc water pump.

Considering the test needs to be done in a dust-free lab, using the unique comprehensive test equipment with high-level filter paper, filter, deionized water ect. Besides, the test results need to be observed under a 200x microscope. The client suggested that they would conduct the test on their own side, in order to ensure the accuracy of the experimental results. TOPSFLO fully respected client's choice and support them positively, and arranged the fastest international express delivery samples to them.

1st Time Samples Testing

After receiving of the first time samples, the client conducted strict test under its proprietary testing conditions and sent back their testing evaluation (as shown in the below picture). There were still some impurities and particles, which did not 100% meet their demands. However, one thing for sure, compared with other brands water pump tested by the client before, the results have been significantly better. Their R&D engineer hope TOPSFLO can provide new solution samples for continue testing.

Picture of the filter magnified 200 times of 1st Time sample testing

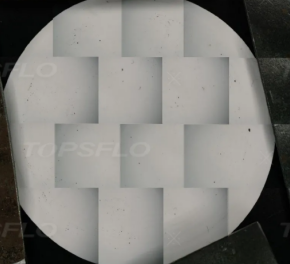

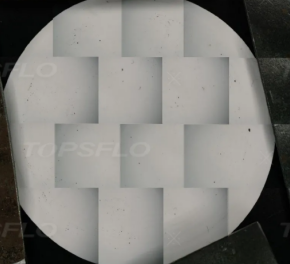

2nd Time Samples Testing

Upon receipt of the test results, TOPSFLO R&D Dept. organized a materials research team to conduct a full set of new materials R&D team for the pump. After three months of comparative experiments, two imported materials were selected to customize the second time samples for the client. Once again the client did real testing and feedback that the results were further improved compared with the first time samples. However, the samples still failed to meet their standards and requirements of "0 particle, 0 impurity".

Picture of the filter magnified 200 times after the 2nd Time testing

From the test report to know, the new customization materials have basically met the standard for medical deionized water acceptable particles. Actually, such experimental results were acceptable by other medical clients. Whereas, as the world’s top Medical Technology Company, this client has been practicing the world’s highest standards to test every part. The members of the TOPSFLO materials R&D team decided to keep tracking of this project. The high requirements and high standards of customers are the driving force for them to make continuous improvements. And it’s also a great opportunity for TOPSFLO to study and improve with the world's top medical equipment manufacture.

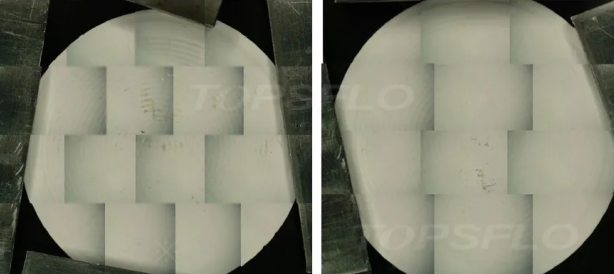

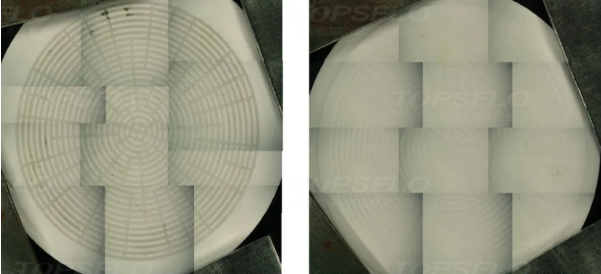

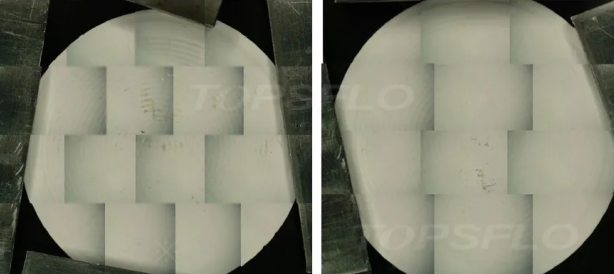

3rd Time Samples Testing

The TOPSFLO materials R&D team made up their minds to speed up the project progress. They sourcing more safer and reliable raw materials worldwide. Four months later, TOPSFLO had gone through dozens of material analysis and tests, and provided customer with new customized TL-C01 centrifugal water pump using imported raw materials once again.

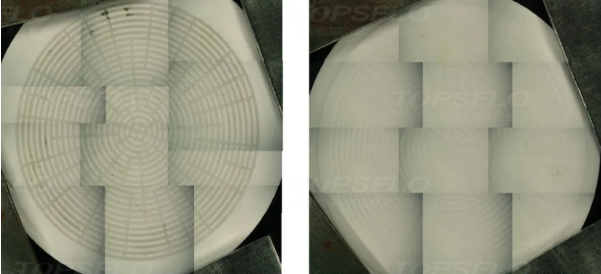

Picture of the filter magnified 200 times after the 3rd Time testing

After 30 days of continuous circulating for the deionized water, the brushless DC water pump provided by TOPSFLO still without particles and impurities precipitated, which means the new solution didn’t cause any pollution to the deionized water. The test results completely met with the "0 particle" standard of this client. Then 3-month continuous test was conducted, TOPSFLO water pump were still free of impurities, which was far beyond the client's expected standard. Moreover, the client actually collected a number of pump from different suppliers around the world for real testing, while only the pump from TOPSFLO passed the test.

Later, the client expressed special thanks to TOPSFLO by email. Due to the Covid-19, sometimes the engineers were even unable to go to their lab for real testing, which seriously affected the progress of their project plan. However, in the course of more than one year of testing, TOPSFLO responded to the client’s high requirements without any delay, and provided them with new solutions and the fastest technical support. The spirit of continuous research and never giving up is as moving as the perfect test results.

Since TOPSFLO established, who always positioned to "export to high-end markets in Europe and America", and in line with the highest global standards. The standards set in R&D, production, and quality control are all higher than other domestic counterparts, and keep pace with internationally brand Bosch, Iwaki, and Nedic . TOPSFLO has been trusted and highly praised by lots of global famous brands. In the process of serving for high-standard customers around the world, TOPSFLO kept studying and never gave up, which has also been widely praised by many world-renowned customers.

TOPSFLO hopes to provide more references for global medical equipment customers, with this breakthrough in pump raw materials and sharing of the experimental process. At the same time, TOPSFLO hopes that all customers in the medical equipment industry can stick to the high standards and benefit the world with truly safe and reliable equipment to worldwide consumers .

.jpg)