Recently, TOPSFLO engineers received feedback from a customer. When the customer tested 48W

mini water pumps from TOPSFLO and other

mini dc motor pump manufacturers, they found that they show the same specification in the label, both are around "24L, 11M", but the parameter results quite different under specific operating points.

The customer tested at a working point of 9.5M, and the TOPSFLO pump got a flow rate of 6.3L/min, while another product only got a flow rate of 3.24L/min, which is only half of the flow rate of the TOPSFLO mini motor pump.

The customer is very confused. Why is there such a big difference in flowrate between two products with the same nominal specification? The following will reveal the secrets for you!

It can be seen from the above figure that the test results are very different. The main reason is that the working efficiency of the two pumps is different. When the efficiency of the pump is higher, it means greater output power it is when under the same power, and less power is wasted.

When we analyze the factors which affect the performance of the pump, one of the important factors is the motor. The efficiency of the traditional AC motor is generally 30%, and it is generally 15% after being converted into the output of the water pump, while the efficiency of the DC brushless motor itself can reach more than 60%, so the efficiency after output is also higher.

Then, the customer tested the same

DC brushless mini water pump, why is there still such a big gap in performance? Because the research history on DC brushless pumps in China is not very long, and the manufacturers with mature technology are even rarer. Efficiency conversion is still a great technical obstacle for most manufacturers. Some manufacturers only stays in "making the pump to run", and they don't care about the key performance issue behind "running" at all.

What are the benefits of a high-efficiency mini water pump?

After years of in-depth research and market feedback, TOPSFLO has come to the conclusion:

1. Under the same power, the higher the efficiency, the greater the output performance. As shown in the previous customer test results, for the same 48W water pump, the flow rate of the

TOPSFLO mini motor water pump is twice that of other manufacturer;

2. Under the same power, the higher the efficiency, the lower the temperature rise, and the longer the life span. Since more power is used to output, the power wasted for heat generation is reduced accordingly, so that the pump generates lower heat and lower temperature rise, and the loss of components and motors is smaller, and the life of the pump is longer.

3. The higher the performance, the more power saving. Using a more efficient water pump, you can use less power to get the performance, which will save more power. Especially in some environments with limited power supply, such as battery power supply and solar panel power supply, the benefits of using high-efficiency water pumps are obvious;

4. The higher the efficiency, the smaller the size of the pump with the same parameters, thus saving the customer's use space.

How is a high-efficiency pump refined?

How is a high-efficiency pump refined?

The birth of a high-efficiency pump is the result of the joint efforts of the pump manufacturer's technical team, hardware equipment, long-term manufacturing experience and other comprehensive strengths.

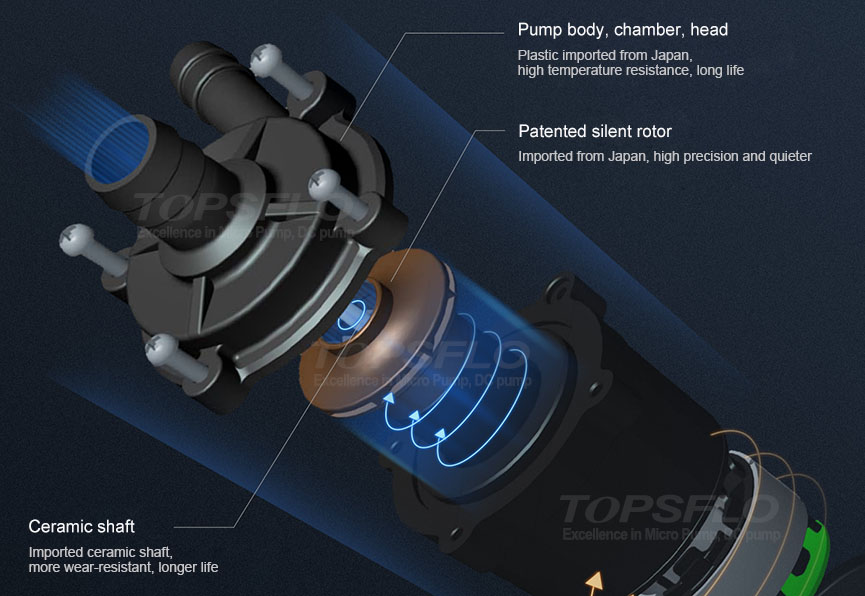

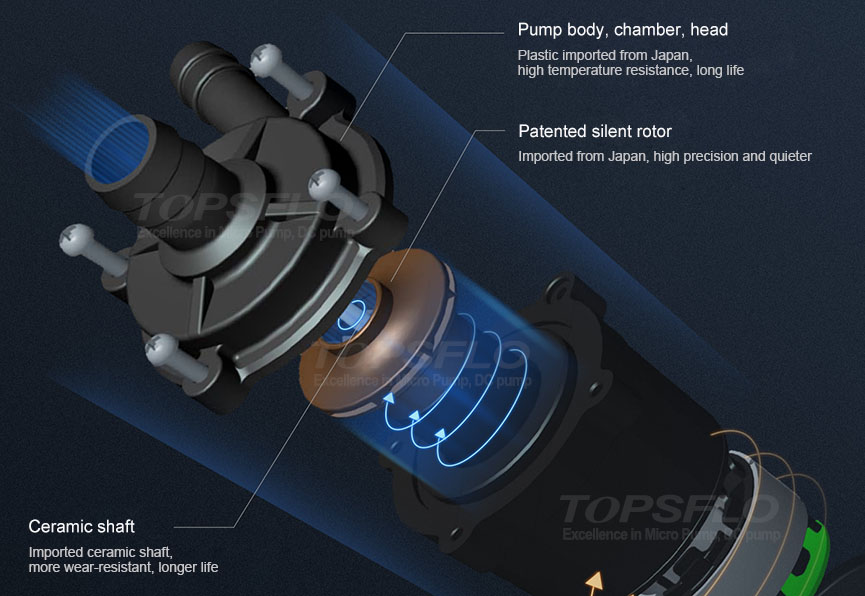

First of all, we need powerful manufacturers and an experienced team of micro-pump engineers, including motor engineers, electronic engineers, structural engineers, fluid engineers, etc. Since the efficiency is an indicator considered from the initial design stage of the pump, it is the result of the comprehensive design of the motor, electronics, structure, fluid, etc.

Secondly, a set of advanced testing equipment and strict testing procedures are required. TOPSFLO invests no less than 10% of its sales in research and development every year, and has built a professional experimental center integrating analysis, testing and verification, and four laboratories that meet the standards of CNAS national laboratory accreditation. The R&D tests are stricter than industry standards, including motor simulation test, comprehensive analysis test of efficiency, etc.

Thirdly, it is necessary to focus on the industry for unremitting research and technology precipitation. Actually our domestic research on brushless DC pumps has been less than 10 years, and there are very few companies that have cultivated the industry for 17 years like TOPSFLO. For manufacturers, they must have the spirit of continuous pursuit of high quality to achieve technological breakthroughs and precipitation. As the first domestic company to enter the miniature brushless DC pump industry, TOPSFLO has independently developed and owned more than 50 industry patents, accumulating core technologies for Chinese

brushless DC pump industry.

Over the past 17 years, TOPSFLO has been adhering to the concept of "continuous self-transcendence, leading the progress and breakthrough of the micro-pump industry with technological innovation", and strives to make the pump perform more efficiently under the given power, and at the same time achieve lower heat generation, lower power consumption, quieter and more space-saving. This is an indicator that will be fully considered and analyzed at the beginning of the design of each TOPSFLO pump, which is also an important reason why many customers feel the high quality and good performance after the actual measurement of the TOPSFLO pump.

.jpg)