About the Laser Tube Cooling for 3D Laser Printer

2023-03-27

As the Ministry of Education attaches great importance to students' quality education, more and more schools and families begin to pay attention to children's hands-on ability. 3D printers (also known as 3D laser engraving machines) have become widely used in school and family education.

The speed and lifespan of a 3D printer are closely related to its key component, the laser tube. At present, it is generally considered to use a CO2 laser tube of about 40W for home use, and the speed is relatively fast.

Today, let me show you the product structure and cooling method of CO2 laser tubes. This will help you better choose a high-quality and durable 3D printer.

Structure of CO2 Laser Tube

The CO2 laser tube is composed of CO2, nitrogen, hydrogen and other gases. With a laser wavelength of 10.6 μm, the laser beam generates a power of more than 20 kilowatts, which can achieve continuous work. It is often used in laser marking machines and laser cutting machines. CO2 laser tubes are used in a wide range of applications.

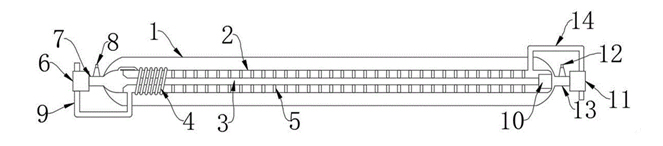

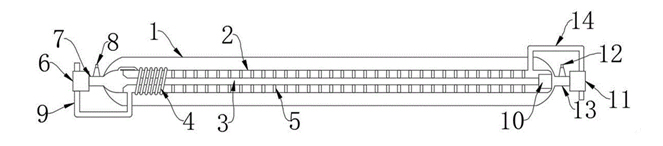

(Cooling structure diagram of CO2 laser tube)

The basic structure of the CO2 laser tube is shown in the figure above. It is mainly composed of hard glass, resonant cavity and electrodes.

The hard glass part is composed of a discharge tube, cooling tube, gas storage tube and gas return tube.

The discharge tube is a key component in CO2 lasers, which basically determines the characteristics of the laser output.

The function of the cooling tube is to cool the working gas, maintain a stable output power, and prevent the discharge tube from bursting due to heat during the discharge pumping process.

The function of the gas storage tube is to increase the gas storage capacity of the gain medium and enhance the mechanical strength and stability of the discharge tube.

The air return pipe can improve the unbalanced distribution of the voltage between the electrodes caused by the electrophoresis phenomenon.

Pain Points of CO2 Laser Tube Cooling

There are two types of laser tubes with the same power: catalytic type and sealed-off type. The catalytic type CO2 glass laser tube (enhanced type) is an upgraded product of the traditional sealed-off laser tube. The service life and power are greatly improved by coating the nano-high-efficiency catalyst film in the discharge tube, and the adjustable inner cavity structure greatly improves the light quality of the laser tube, so that the cutting efficiency and engraving precision in the application are greatly improved.

Whether it’s the catalytic type or the sealed-off type CO2 laser tube, a lot of heat will be generated during working, and the temperature of the discharge tube will be too high. However, its own heat dissipation capability is limited, and the temperature will continue to rise. Thus a cooling system is needed to cool down the internal temperature of the laser tube.

At present, there are two main methods of CO2 laser tube cooling: air cooling and water cooling.

Air cooling is often used for low-power lasers, while water cooling covers the entire power range that CO2 lasers can achieve. The effect of water cooling is generally 3-5 times that of air cooling, which can effectively avoid the problem of equipment burn-in caused by poor cooling effects.

Generally, household 3D printers can directly integrate cooling water pumps into the equipment, while large-scale commercial high-power printers may consider adding a chiller for cooling.

The laser chiller is a right-hand assistant for CO2 laser tube cooling. It has a built-in water cooling system. The cooling liquid is circulated through the operation of the water pump, which takes away the high temperature of the laser tube and returns it to the evaporator. After reducing the water temperature, it returns to the laser tube, which can constantly keep the CO2 laser tube equipment within an appropriate range, guaranteeing for the laser equipment to work for a long time. The laser chiller has a water temperature adjustment function, and the water temperature setting range is from 5 to 35°C, which can meet the individualized temperature setting requirements of different CO2 laser equipment.

Due to the unstable structure of the cooling system of the common CO2 laser tubes currently on the market, excessive fluctuations in the flow rate of the cooling water can break the power generation tube.

Therefore, whether it is a household or commercial 3D printer, a high-quality laser printer cooling water pump is urgently needed on the market.

Laser Tube Cooling Water Pump Recommendation

Since entering the laser tube cooling industry in 2014, TOPSFLO has nearly 10 years' experience in mass production and verification. Laser printer cooling water pumps TL-B03, TL-B10, TL-C01, etc. are very popular in high-end markets in Europe and America.

The top three customers in the US laser tube industry said: "The cost of laser tubes is high, which is the key to ensuring the normal operation of the product. Liquid cooling reliability is the first condition for us to choose a water pump supplier. We tested several water pumps simultaneously and compared them. Only TOPSFLO’s water pump has the highest cooling effect, and it has passed high and low temperature tests without cracking or leaking. Only high-quality water pumps can ensure that our laser tubes will not break.”

TOPSFLO’s professional laser engraver cooling water pump has a high flow rate and large water head. It can run continuously for 24 hours and has a life span of up to 30,000 hours. 100% of the key electronic components are imported and traceable. The rotor is injection-molded by a Japanese-funded enterprise with high precision and no leakage. Small size and easy installation, it’s ideal for C02 laser tube cooling.

TOPSFLO is committed to providing strong support for the 3D printer and laser tube cooling industry. In the future, we will continue to innovate and make breakthroughs to provide the industry with more stable and reliable micro pump products and fluid power solutions.

.jpg)